Quality

Quality assurance

Our aim is to offer the distribution of electronic components in the highest possible, flawless quality in order to optimally meet our customers’ requirements and expectations.

Customer satisfaction and an honest, respectful cooperation are our top priority.

Quality assurance

Our aim is to offer the distribution of electronic components in the highest possible, flawless quality in order to optimally meet our customers’ requirements and expectations.

Customer satisfaction and an honest, respectful cooperation are our top priority.

What we offer:

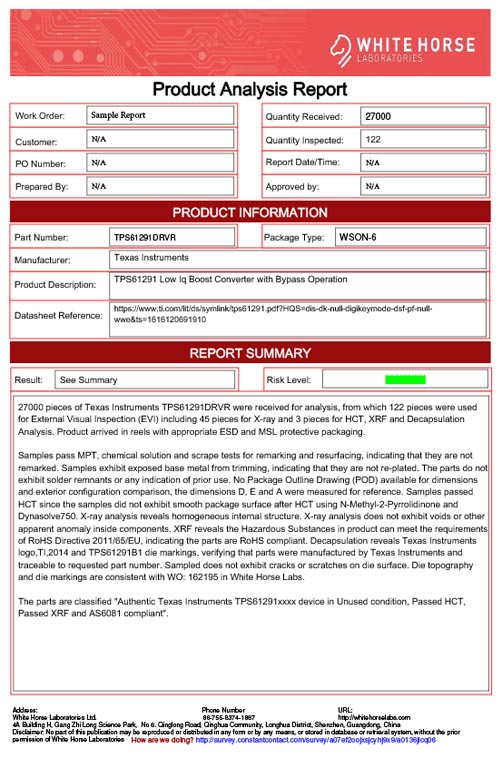

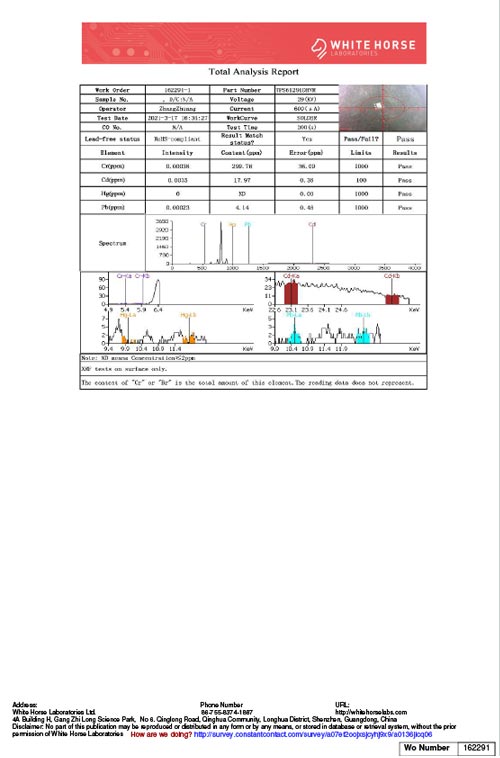

• Use of certified and independent test laboratories to verify quality, functionality and originality

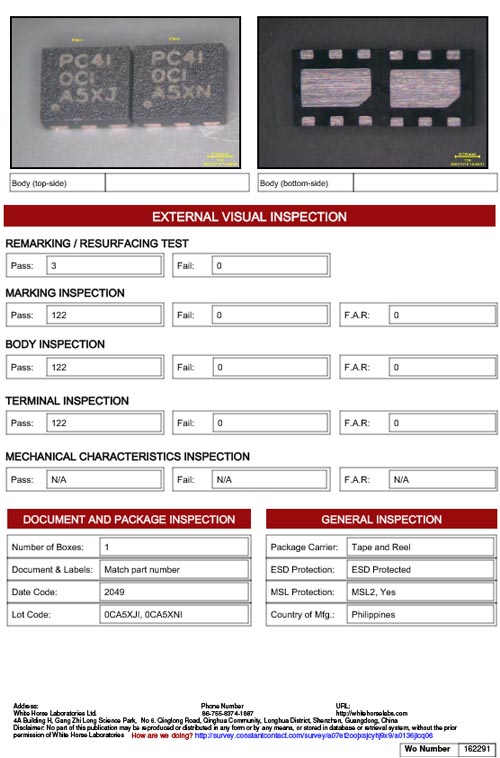

Personal detailed inspection of incoming and outgoing goods with digital image recording

Comparison of packaging and labels against reference image data and inspection of components

Prevention of counterfeit products

We’ve developed a systematic process to prevent counterfeit products. We cooperate with independent, certified test laboratories to check individual components.

This is how we can ensure that components are impartially checked for originality, quality and functionality.

Possible test spectrum during the components’ inspection:

External Visual Inspection

Parametric and Functional Test

Curve Trace

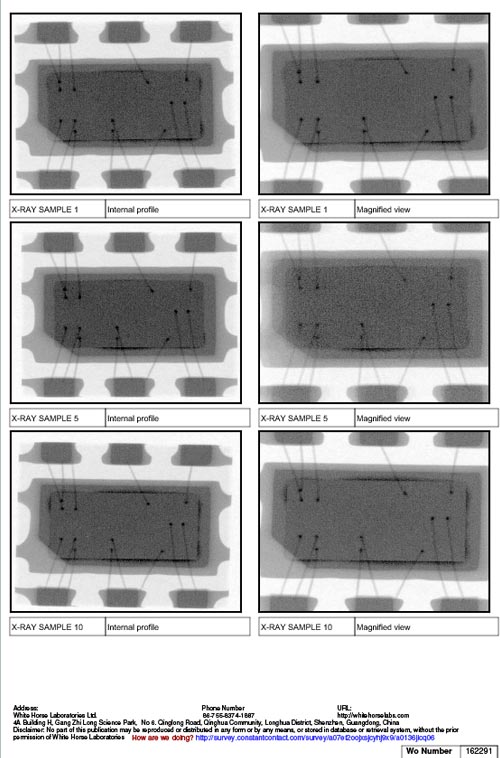

X-ray Analysis

Scanning Acoustic Microscopy (TSAM and CSAM)

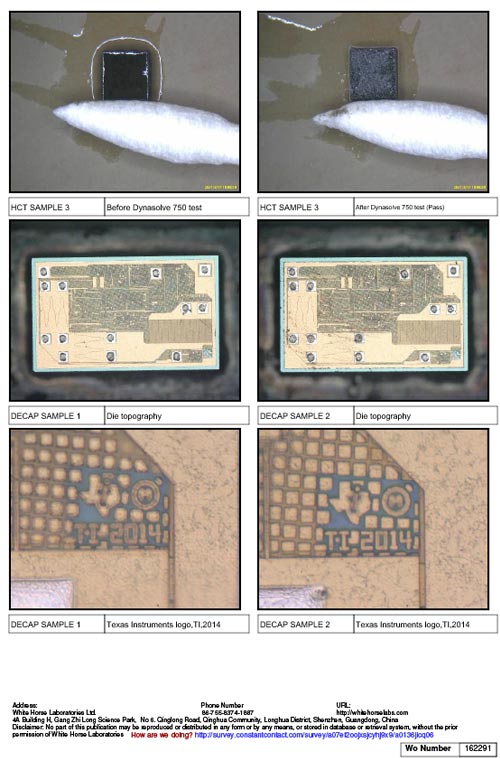

Decapsulation and Die Analysis

Cross-Section

High Magnification Microscopy

Scanning Electron Microscopy (SEM)

Energy Dispersive X-ray Spectrometry (EDX/EDS)

Liquid Crystal (Hotspot) Testing

FTIR

Our standard testing procedure

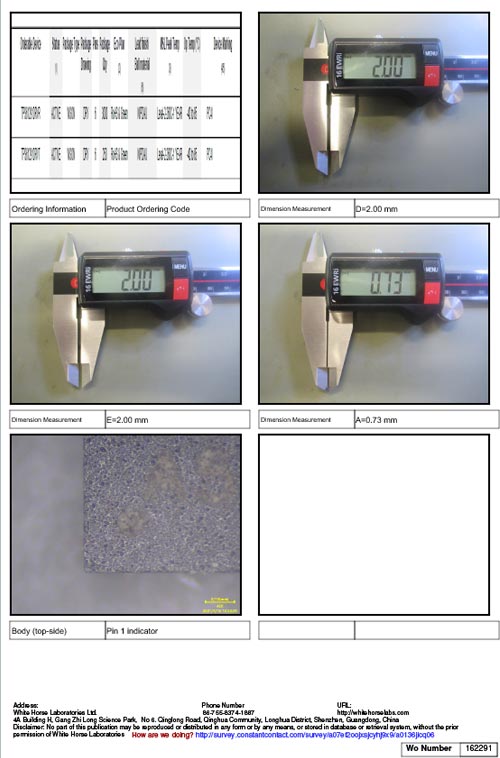

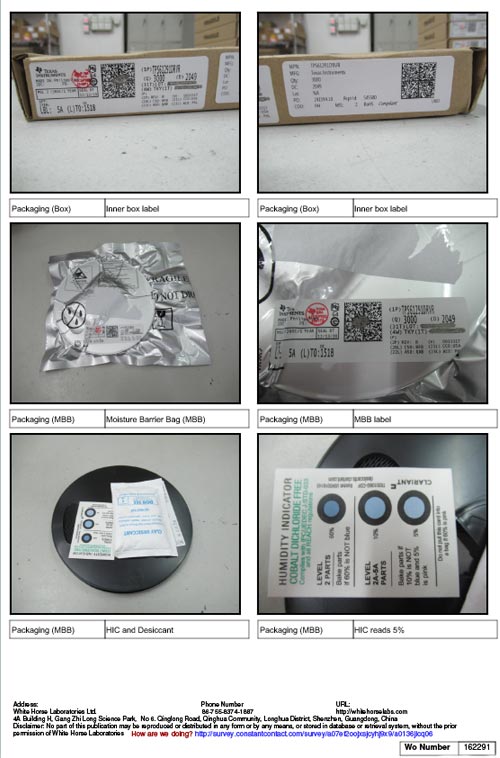

Documentation of delivery condition and visual inspection of packaging

Checking packaging for originality and any damages.

Verifying that MSL and ESD protection measures are in place and intact.

External visual inspection according to IDEA-STD-1010

Checking electrical function

X-ray inspection

Examination of terminal contacts and solder joints (anomalies, cracks). Analysis for ESD and EOS damages.

Solderability check

Determination of workability of components in the soldering process. Determination of solderability differences of various component batches/components of different ages.

Chemical component opening

Determination of manufacturer (originality).

Examination of bonding points, micro-cracks, structural defects.

Provision of test report for customer (excerpt by way of example)

Our suppliers

Selecting our suppliers is the first important step in ensuring that the highest quality standards are met. As a supplier of electronic components, Components at Service GmbH can ensure compliance with high quality standards due to long-term partnerships with our suppliers as well as regular supplier audits.

Our monthly supplier audits assess factors such as quality compliance, inventory management, on-time delivery, material origin, and safety and environmental conformity.

Our employees

Quality can only be ensured and maintained by motivated, qualified employees, which is why we offer our team individual development opportunities as well as individual training and continuing education.

Components at Service GmbH gives all employees an opportunity to realize and advance their own projects.

Such a basis of trust results in long-term intrinsic motivation and thus to maximum customer satisfaction.

Our employees

Quality can only be ensured and maintained by motivated, qualified employees, which is why we offer our team individual development opportunities as well as individual training and continuing education.

Components at Service GmbH gives all employees an opportunity to realize and advance their own projects.

Such a basis of trust results in long-term intrinsic motivation and thus to maximum customer satisfaction.

Our processes

We are certified according to DIN EN ISO 9001: 2015. This means that all our processes are strictly regulated according to the requirements of this quality standard.

DIN EN ISO 9001:2015 is the most widely used, most important quality management standard, both nationally and internationally. It serves as a basis for a continuous improvement process, first and foremost to fulfil customer requirements and to strive to meet customer expectations.

Our warehouse

Storing electronic components requires protection against electrostatic discharges. That is why our storage area is ESD-protected according to DIN EN 61340-5-1/-5-3.

The structure of our warehouse is optimized so that the handling of incoming as well as outgoing goods functions smoothly in order to maintain on-time deliveries and the usual high quality.

Our warehouse

Storing electronic components requires protection against electrostatic discharges. That is why our storage area is ESD-protected according to DIN EN 61340-5-1/-5-3.

The structure of our warehouse is optimized so that the handling of incoming as well as outgoing goods functions smoothly in order to maintain on-time deliveries and the usual high quality.

Location

Keltenring 15

82041 Oberhaching